Planograms are designed to be the blueprint for retail success - guiding product placement, maximizing shelf visibility, and driving sales. Yet, many retailers face a common challenge: what is planned on paper (or software) does not always translate to what appears on the store’s shelf. This disconnect between planogram compliance and store execution can significantly impact performance. Understanding why this gap exists and how to bridge it, is critical for retailers aiming to turn planogram strategy into real-world results.

What Is Planogram Compliance?

Planogram compliance refers to how closely a store follows the approved planogram layout. This includes:

- Correct product placement.

- Accurate facings and quantities.

- Proper shelf positioning and spacing.

- Alignment with promotional and seasonal guidelines.

High compliance ensures consistency across stores, protects brand standards, and helps retailers achieve the sales outcomes envisioned during the planning stage.

What Is Planogram Execution?

Execution is the practical implementation of a planogram at the store level. It involves store staff physically setting shelves, replenishing stock, handling substitutions, and adapting layouts to real-world constraints like space limitations or supply issues. Even a well-designed planogram can fail if execution is inconsistent or incomplete.

Why Does the Gap Exist Between Design and Reality?

Several factors contribute to the compliance–execution gap:

- Operational constraint: Limited staff, time pressure, and competing priorities often lead to shortcuts during shelf setup.

- Stock availability issues: Out-of-stocks, delayed deliveries, or incorrect assortments force store teams to deviate from the planned layout.

- Lack of clarity or training: If planograms are complex or not clearly communicated, store teams may misinterpret layouts or ignore certain guidelines.

- Reducing out-of-stock during peak days: Out-of-stocks during Christmas does not just mean lost sales—they mean lost customers. AI continuously monitors shelf performance and flags potential stock risks. Retailers can use AI-driven shelf analytics to detect fast-depleting SKUs like candies and beverages to boost sales.

- Store-specific variation: Differences in store size, fixtures, or local demand may cause teams to modify planograms without approval.

- Manual processes and errors: Without automation or real-time validation, manual execution increases the risk of errors and inconsistencies.

The Impact of Poor Compliance

When execution does not match design, retailers face:

- Lost sales opportunities due to poor product visibility.

- Inconsistent customer experience across locations.

- Reduced effectiveness of promotions and launches.

- Lower ROI on planogram planning efforts.

- Difficulty in analyzing performance accurately.

Simply put, a non-compliant planogram is a missed opportunity.

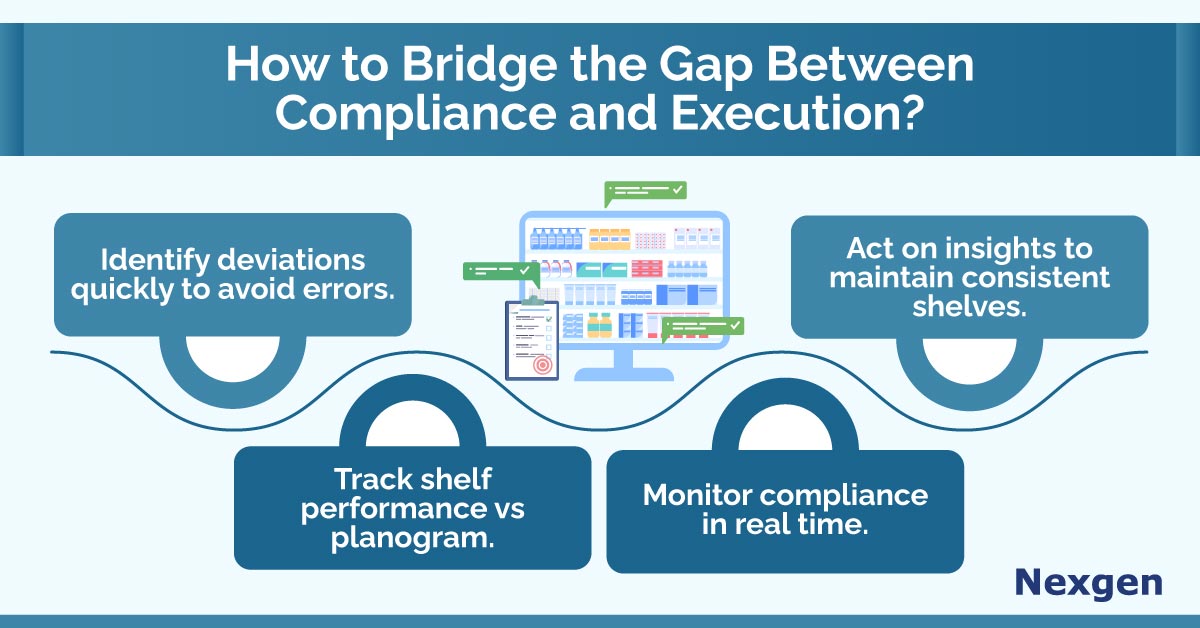

Bridging the Gap Between Compliance and Execution

To align planogram design with in-store reality, retailers need a combination of technology, process, and people-focused strategies:

- Simplify planogram design: Simple planograms reduce confusion on the store and minimize execution errors. They also speed up implementation, helping stores maintain consistency across locations.

- Use digital planogram tools: Cloud-based planogram solutions to allow real-time access, version control, and instant updates across stores. If there is an issue like wrong product placement, missing items, or incorrect shelf sizes, store managers can easily solve this with planograms. This also helps the audit team and field sales team verify whether the execution is correct in the first place.

- Enable execution visibility: Dashboards, reports, and store-level feedback help track compliance and identify gaps early. It also supports accountability by clearly showing where execution standards are being met or missed.

- Integrate sales and inventory data: Data-driven planograms help prioritize high-performing products and prevent overstocking or gaps on shelves. This alignment leads to better shelf productivity and improved sales outcomes.

Overview of Nexgen POG

Nexgen POG is a robust and user-friendly cloud-based visual merchandising tool. It is designed for quick and efficient planogramming with minimal effort. Planograms in retail can be designed by easily dragging and dropping the products. The multi-device compatibility feature of POG allows you to obtain, share and edit on any device, including your phone. It helps in designing store-specific planograms for increased product visibility and sales.

Get Your Free Trial Today!