Picture this: a customer walks down an aisle, ready to buy a product from your store. They scan the shelf, only to find it empty. Frustration sets in, and they walk out from your store. This scenario, known as a "shelf gap" or "out-of-stock" (OOS), is a retailer's nightmare. It leads to lost sales, dissatisfied customers, and a dent in your brand's reputation. By using planograms, retailers can efficiently monitor and eliminate shelf gaps in real time, ensuring shelves are always fully stocked and visually appealing.

Understanding Shelf Gaps and Their Impact

Shelf gaps occur when a product is missing from its designated space on the shelf, leading to empty spots. These gaps can result from various factors such as poor inventory management, inefficient restocking processes, or unexpected demand surges. The consequences of shelf gaps include:

- Lost sales due to unavailability of products.

- Frustrated customers who may switch to competitors.

- Reduced brand trust as shoppers perceive inconsistency in stock availability.

- Inefficient store operations caused by frequent manual stock checks and reactive replenishment.

How Planograms Help Identify Shelf Gaps in Real Time?

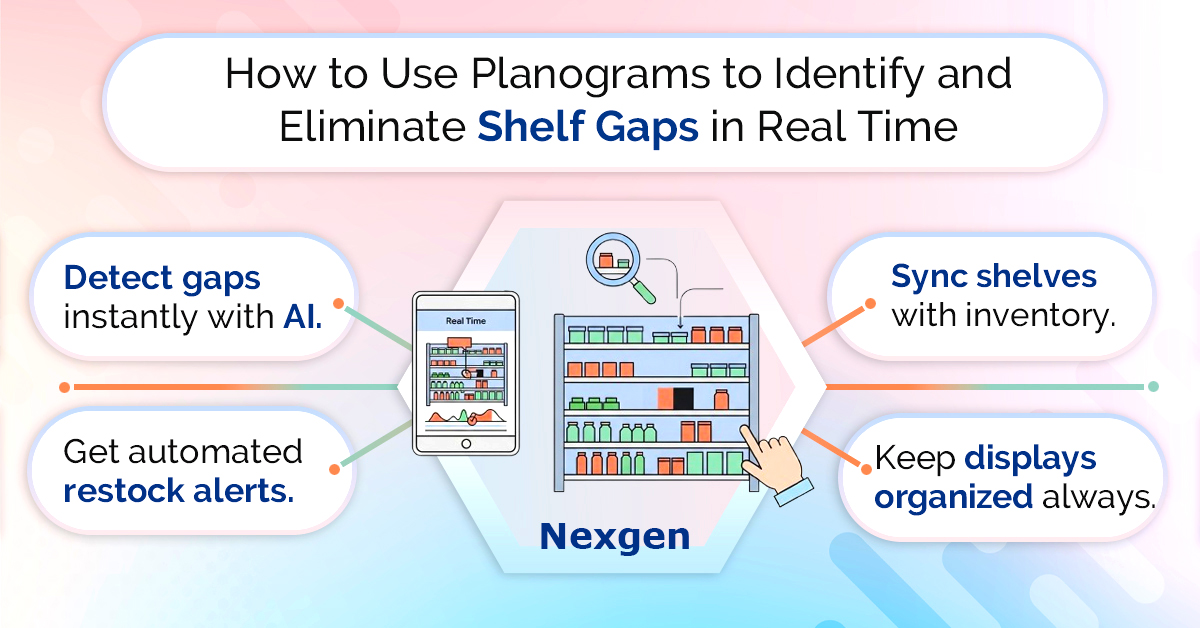

Planograms are detailed visual representations of how products should be displayed on store shelves. With modern technology, AI-powered and cloud-based planogram solutions can help retailers monitor and address shelf gaps efficiently. Here’s how:

1. Real-time shelf monitoring with AI-powered planograms.

AI-driven planogram solutions use image recognition and machine learning to scan store shelves in real time. These systems compare actual shelf conditions with the ideal planogram to detect gaps instantly.

- Immediate identification of missing products.

- Reduced reliance on manual checks.

- Faster response time to replenish empty spaces.

Automated alerts and restocking notifications.

Cloud-based planogram software can send automated alerts to store associates when shelf gaps are detected. This ensures that gaps are addressed before they impact sales.

- Quick response to restock items.

- Improved inventory accuracy.

- Enhanced operational efficiency.

3. Seamless integration with inventory management systems.

Modern planogram solutions integrate with inventory management systems to track stock levels and predict when restocking is needed.

- Prevents stockouts by forecasting demand trends.

- Synchronizes shelf replenishment with supply chain data.

- Reduces overstocking and understocking issues.

4. Improved merchandising compliance

Planograms ensure products are always placed in their correct positions, preventing misplaced items that could lead to perceived shelf gaps.

- Consistent shelf organization.

- Better visual merchandising execution.

- Higher shopper engagement and satisfaction.

Implementing a Planogram-Based Strategy to Eliminate Shelf Gaps

To effectively use planograms for real-time shelf gap management, retailers should:

- Adopt AI and Cloud-based planogram solutions: Choose a planogram tool, such as Nexgen POG which offers real-time tracking and integration with inventory systems.

- Train store associates: Ensure employees understand how to use planogram alerts and restocking notifications.

- Conduct regular shelf audits: Use planogram reports to monitor store performance and optimize product placement.

- Leverage data analytics: Analyze shelf gap trends to improve stock replenishment strategies.

Overview of Nexgen POG

Nexgen offers store-specific planograms for clients that optimize sales and achieve category objectives. We create customized planograms for your business to ensure that these are better aligned with your goals and merchandising strategies. Our expertise in planogram automation helps us build planograms faster, better, and consistently. Whether it is creating a planogram from scratch, or a typical reset, we have the knowledge, tools, and experience to get the job done for you.

Get Your Free Trial Today!