As e-commerce surges ahead in 2025, the demand for seamless fulfillment has never been greater. Dark stores and micro-fulfillment centers (MFCs) have emerged as critical players in ensuring rapid delivery and efficient inventory management. But what elevates these operational hubs to true efficiency? With planograms, retailers can optimize every inch of retail and fulfillment space. Here is how planograms are revolutionizing dark stores and MFCs, making them the backbone of modern e-commerce.

Understanding Dark Stores and MFCs

Dark stores are retail spaces repurposed into warehouses dedicated to fulfilling online orders. They lack the bells and whistles of customer-facing stores but excel in functionality and speed. Similarly, micro-fulfillment centers are compact, automated hubs located close to urban areas, designed to minimize the time and cost of last-mile delivery. Planograms used in brick-and-mortar retail for product placement are now indispensable for dark stores and MFCs. They provide a visual blueprint for how and where products should be stocked, ensuring maximum efficiency and accuracy in picking and packing.

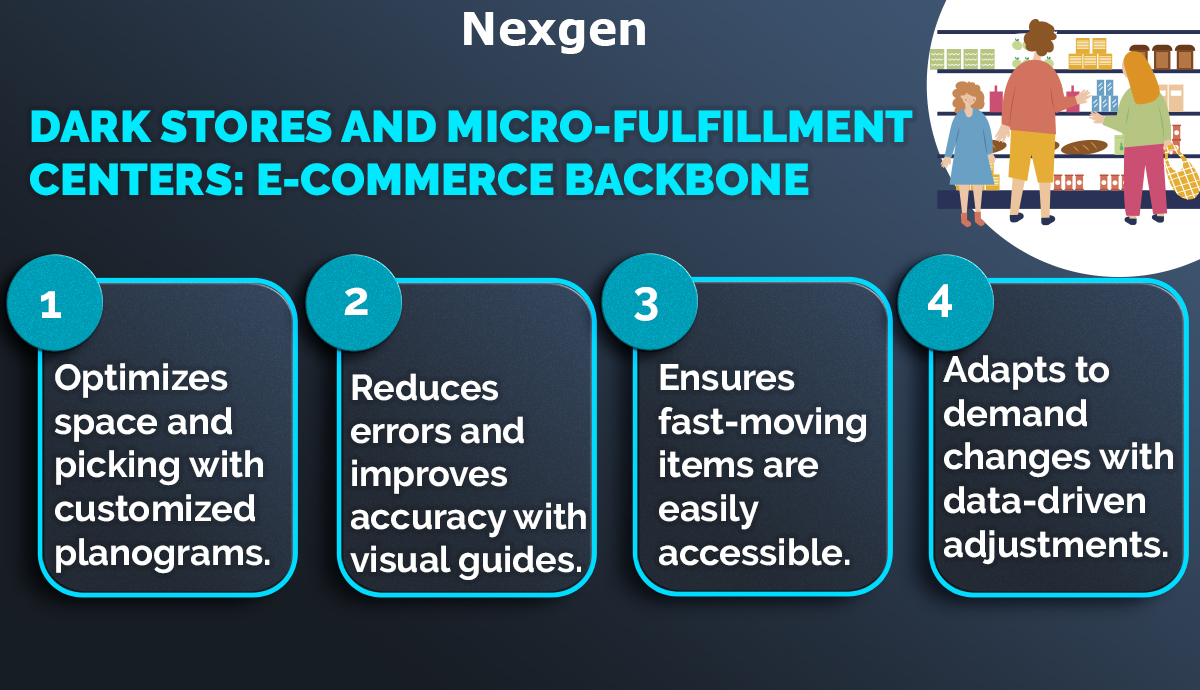

Benefits of Planograms in Dark Stores and MFCs:

- Optimized space utilization: Planograms ensure that every shelf, bin, and rack is used effectively, avoiding wasted space.

- Streamlined picking processes: Products are placed logically, reducing picker travel time, and increasing order accuracy.

- Improved inventory turnover: Fast-moving items are placed in easily accessible areas, while slower-moving goods occupy secondary spaces.

- Reduced human error: Visual guides help warehouse staff locate items quickly, minimizing mistakes.

- Data-driven adjustments: Planograms can be updated based on real-time sales data, ensuring stock levels and placements align with demand trends.

Adapting Planograms for Dark Stores

Unlike traditional retail, dark stores do not need to consider customer-facing aesthetics. Instead, planograms focus on operational efficiency:

- Vertical space optimization: In dark stores, vertical shelving is crucial for storing a larger volume of products in a smaller space, allowing more items to be picked up and packed efficiently. For example, in a grocery store, bulky items like canned goods may be stored higher up on shelves, while lighter and frequently ordered products like snacks can be placed at waist height for quicker access.

-

Zone-based picking: By categorizing products into specific zones, dark stores can reduce the time it takes for workers or robots to fulfill orders by limiting their search area. For instance, a dark store may designate a "snack" zone near the packing station, so when a snack order comes in, it can be picked quickly and efficiently without crossing other product zones like frozen foods or beverages.

- Flexibility for demand fluctuations: Planograms in dark stores are designed to be agile, allowing retailers to rearrange stock and respond to demand spikes for seasonal or promotional items. For example, during the winter holiday season, a dark store may reassign high-demand items like Christmas decorations or gifts to prime positions closer to the packing area, ensuring faster order fulfillment during peak periods.

Overview of Nexgen Planogram Services

Nexgen offers store-specific planograms for clients that optimize sales and achieve category objectives. We create customized planograms for your business to ensure that these are better aligned with your goals and merchandising strategies. Our expertise in planogram automation helps us build planograms faster, better, and consistently. Whether it is creating a planogram from scratch, or a typical reset, we have the knowledge, tools, and experience to get the job done for you.

Get in Touch!